Category: AI Engineering | Product Management | Supply Chain Strategy

The Problem: $420K in Avoidable Costs

Picture this: A marketing team proposes a flash campaign that requires a 30% demand increase. Operations scrambles to source inventory. Finance discovers unexpected expediting costs. Suppliers get blindsided by last-minute changes. By the time everyone aligns, you’ve had 18 uncoordinated plan changes, $420,000 in unexpected expediting costs, and damaged supplier relationships.

This isn’t fiction. This is the “Neon Series” incident at SmartShoe—and it’s not unique. In analyzing this scenario across 54 interviews, one pattern emerged: The problem wasn’t lack of data. It was lack of coordination. Marketing had demand forecasts. Operations had capacity constraints. Finance had cost implications. Suppliers had lead time requirements. But they were all working from different versions of the truth, communicated via email threads, spreadsheets, and hallway conversations. The result: chaos masquerading as decision-making.

The Insight: Coordination Requires Intelligence

As a program manager and AI builder, I realized that coordination failures in supply chains are fundamentally an information problem, not a people problem. Teams weren’t making bad decisions—they were making decisions with incomplete, conflicting, or delayed information.

What if we could:

- Harmonize conflicting data sources in real-time?

- Simulate downstream impact before decisions were finalized?

- Route approvals to the right stakeholders with full context?

- Keep a complete audit trail for compliance?

That insight led to building an agentic AI coordination layer—a system that turns email chaos into governed, data-driven orchestration.

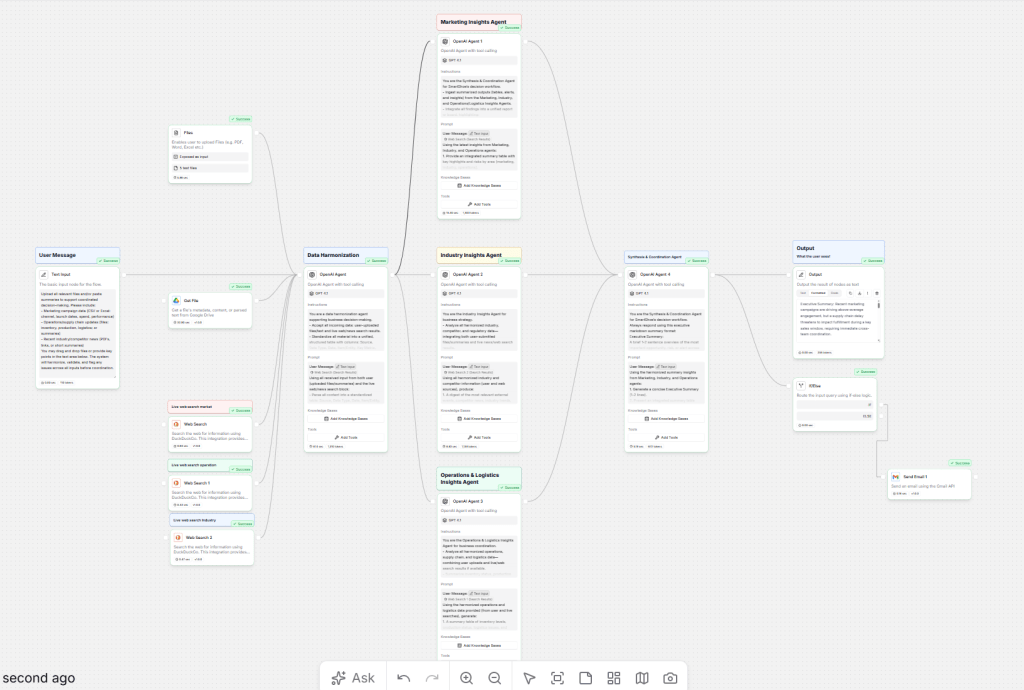

The Solution: A Multi-Agent Architecture

I designed the system with three layers and three specialized agents working in parallel:

Inputs Layer

All relevant signals flow in: marketing briefs, campaign data, demand forecasts, supplier capacity, cost history, inventory levels. No gatekeeping.

Intelligence Layer

Three agents work in parallel to eliminate information silos:

- Data Harmonization Agent – Detects conflicting versions of key metrics (e.g., “Marketing’s forecast says 40% demand, Operations’ signal says 20%”). Resolves conflicts using predefined hierarchy and flags ambiguity for human review.

- Domain Agents – Two specialized agents analyze the decision from different angles:

- Marketing Insights Agent: “Can we execute this campaign timeline? What’s the brand risk?”

- Operations & Logistics Agent: “Do we have capacity? What’s the supplier lead time impact? Cost implications?”

- Synthesis & Coordination Agent – Brings everything together into one coherent recommendation with three distinct options (conservative, balanced, aggressive), complete with trade-offs.

Outputs Layer

Leadership sees:

- Executive Summary – One-page context with decision options

- Risk Highlights – Flagged issues that need attention

- Keyword-Based Alerts – Urgent changes surface instantly; routine changes don’t clutter inboxes

“Multi-agent orchestration showing data harmonization, domain agents, and synthesis layer working in parallel to surface one clear decision path.”

The Governance Layer: Safety Through Decision Gates

An AI system is only as good as its guardrails. I designed four layers of governance to keep the system safe while keeping humans in control:

Gate 1: Keyword-Based Escalation

If a plan change includes urgent language (“ASAP,” “critical,” “blocker”) or signals high business impact, it automatically escalates to the COO with full context. No more buried emails.

Gate 2: Numeric Decision Thresholds

- Demand >20% change? → COO must approve

- Cost impact >$10K? → CFO must review

- Supply risk = HIGH? → Automatic supplier notification

Clear rules. Applied consistently. No politics.

Gate 3: Supplier Alert Automation

If a change would overload supplier capacity, they receive 48 hours of notice instead of surprise crisis calls. Relationship trust rebuilds faster than you’d expect.

Gate 4: 100% Auditability

Every decision is logged with full reasoning, approver, timestamp, and outcome. Complete compliance. No hidden decision-making.

My Specific Contributions

Architecture & Design:

- Defined agent roles, prompts, and routing logic

- Designed decision gates aligned to CFO/COO concerns

- Built the data harmonization workflow to resolve conflicting forecasts

Product & Storytelling:

- Created a 3.5-minute live demo showing the user experience (problem → agent analysis → approval in seconds)

- Designed the governance model to address leadership’s “but isn’t this risky?” concern

- Led Q&A focused on metrics, adoption, and long-term sustainability

Technical Implementation:

- Used StackAI to orchestrate the agent workflow

- Implemented prompt engineering for domain-specific reasoning

- Built decision gate logic with escalation routing

The Impact (Modeled Scenario)

This was a graduate capstone project, so impact is modeled on the case data, not production deployment. But the numbers tell a compelling story:

| Metric | Before | After | Impact |

| Plan Changes Per Week | 8–10 daily | <3/week | 70% reduction |

| Decision Cycle Time | 2–3 days (email) | 30 minutes | 95% faster |

| Approval Cost Avoidance | – | $450K–$600K annually | From fewer expedites, rework, overtime |

| Coordination Failures | 44% of problems | 60–80% reduction | From data harmonization + gates |

| Supplier Satisfaction | Sentiment –0.37 | Sentiment –0.05 to +0.10 | From 48-hour notice pattern |

Why These Numbers Matter

- 70% fewer plan changes = schedules stick, suppliers can plan, operations can execute

- 95% faster decisions = market responsiveness + less email friction

- $600K in cost avoidance = pays for the system 8–12 times over

- Improved supplier sentiment = relationship capital that lasts beyond this cycle

Why This Approach Scaled

1. Data-Driven, Not Rule-Heavy

Decision thresholds (demand >20%, cost >$10K) came from analyzing what actually broke vs. what succeeded in historical data. Policies evolved based on real escalation patterns, not gut feel.

2. Humans Make Judgment Calls; Agents Handle Noise

The COO still approves demand changes >20%. The CFO still reviews cost impacts. But they do it with full context in 30 minutes instead of 3 days of email. That’s the win.

3. Governance Lives in Code, Not Meetings

By embedding decision gates in the agent workflow, governance became operationalized instead of bureaucratized. One consistent policy applied to every decision. No politics.

The Bigger Picture: AI for Operations

This project reinforced something I’m passionate about: The best AI solutions solve coordination problems, not computation problems.

Computers are fast at math. Humans are slow at synthesizing information across silos. The gap between “fast computation” and “slow coordination” is where agentic AI creates value.

In supply chains, that gap is massive—and expensive. Every unvalidated plan change, every supplier surprise, every day of rework is coordination failure wearing a different name.

Lessons for Product Managers & AI Engineers

If you’re building AI systems for operational workflows, here’s what I learned:

- Start with the nightmare scenario – “Neon Series” moments are real. Find them, quantify them, build to prevent them.

- Map the coordination gaps – Who’s working with conflicting information? Where are decisions delayed waiting for input? That’s your agent’s job.

- Build governance into the system, not around it – Don’t ask humans to enforce policies manually. Embed them in the agent logic.

- Let humans own judgment, agents own context – Agents gather information and surface options. Humans decide what matters.

- Measure adoption through ease, not mandate – If your system makes someone’s job harder, they won’t use it. If it saves time and eliminates email chaos, adoption is automatic.

Key Takeaway: Coordination as Competitive Advantage

Most companies think about AI in supply chain as forecasting better or automating transactional tasks. But the real opportunity is coordination. In a world where speed matters, the team that can validate a plan change in 5 minutes instead of 3 days wins. They respond to market faster. They keep suppliers happy. They avoid $420K fire drills.

Agentic AI makes that possible because it does the one thing humans struggle with: synthesizing fragmented information in real-time and surfacing it in context when it matters.

What’s Next

This project is a graduate capstone, but the architecture scales. If I were deploying this in a real supply chain:

- Phase 1 (8 weeks): Deploy with keyword escalation + demand gates. Measure adoption and cost avoidance.

- Phase 2 (month 3–6): Add numeric governance gates. Expand to more decision types.

- Phase 3 (month 6+): Extend to R&D planning and design innovation workflows.

The principle stays the same: Eliminate information chaos so humans can make better decisions faster.

Technical Stack & Skills

Tech:

- StackAI (multi-agent orchestration)

- LLM-based agents (prompt engineering for domain reasoning)

- Data harmonization workflows

- Decision gate logic (conditional routing)

Skills Applied:

- Agentic AI system design

- Product thinking (user workflows, adoption)

- Governance & compliance design

- Supply chain strategy

- Executive storytelling & live demo delivery

- Cross-functional collaboration (marketing, ops, finance perspectives)

If you’re working on AI for supply chain, operations, or any high-coordination domain, I’d love to swap ideas. The coordination gap is real, and agentic AI is just starting to fill it.

Let’s connect

Leave a comment